You Can’t Win by Losing Time

– Our Fast Fielded Solutions Are the Answer

Complete Lifecycle Management

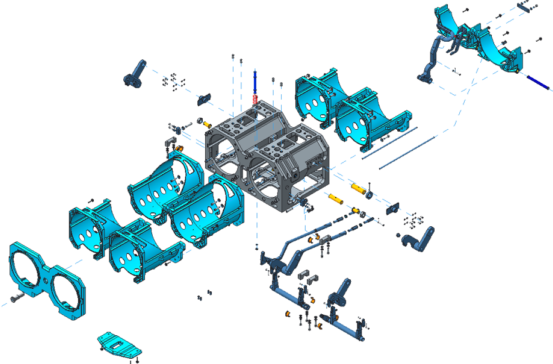

PRODUCT REALIZATION

SolidWorks 3D Solids Modeling, Design, and Drawings

- Physical Prototype Fabrication

- 3-D Printing

- Designed for Manufacturing & Assembly

- Drafting and Documentation

Electro-Mechanical Design

- Electro Mechanical Assemblies

- Digital and Analog Circuit Design

- Multilayer Circuit Card Assemblies

- Cable & Wiring Harness Assemblies

- Electronic Chassis Assemblies

Build-to-Print Production

- High Mix – Low Volume

- From LRIP to Full Rate Production

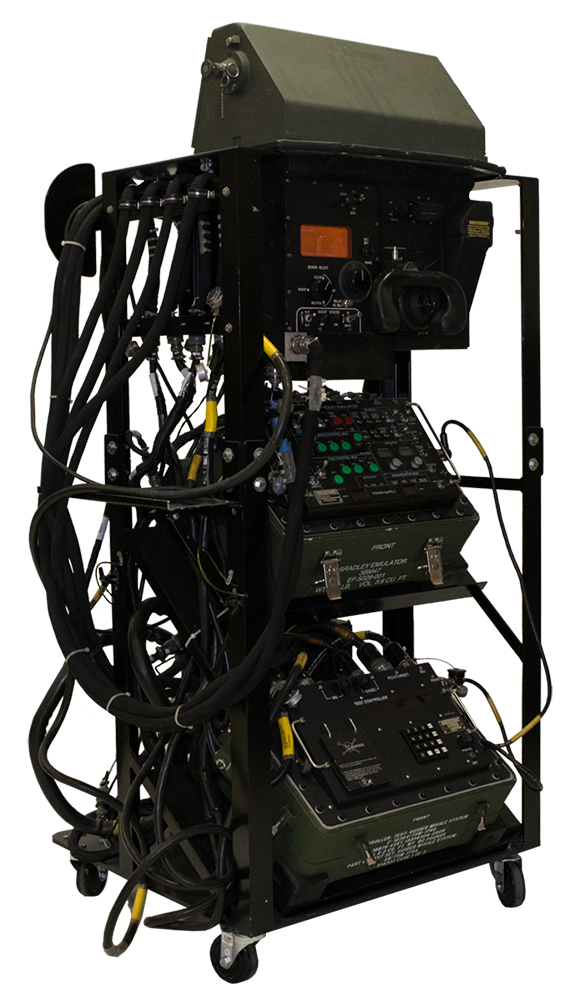

INTEGRATION & TESTING

Platform Hardware Integration

- Target Acquisition, EO/IR Sensor Systems

- Integration

- High Voltage/Pulse Power Systems

Air and Ground Platform Integration

M65 Air Launched TOW

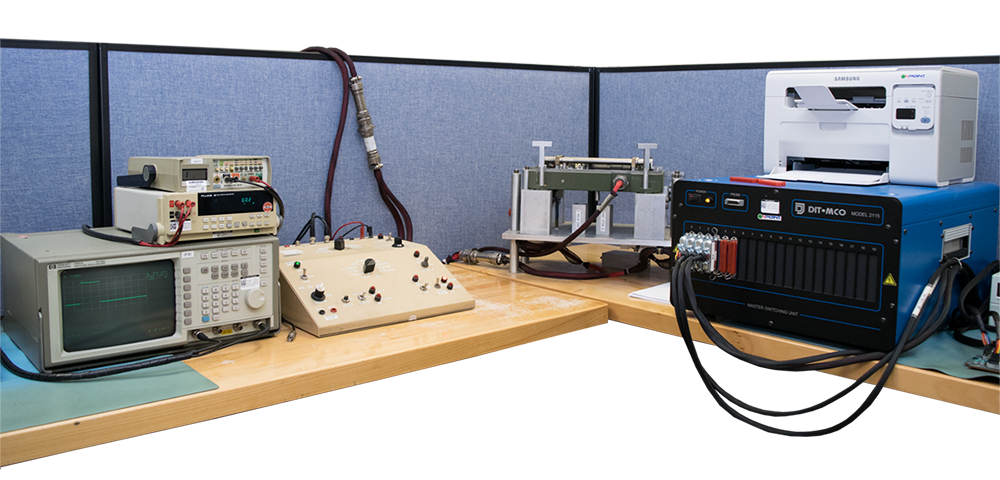

Test, Evaluation, and Qualification

- Test Plan Development

- Aviation and Ground-based DT/OT Planning & Execution

- Live-Fire Range Testing Support

- Finite Element Analysis (FEA)

- Environmental Stress Screening

- Vibration – Random Dual Axis

- High and Low Temperature

- Thermal Shock

- Mechanical Shock

OBSOLESCENCE MANAGEMENT

Component Event Monitoring

- Provide impact analysis of each change in engineering, supply chain, production, quality maintenance

- Identify high-risk components in active products

- Provide warnings and enable obsolescence planning

- Analyze similar COTS parts for form, fit, function, and ruggedization to identify potential replacement

Part Obsolescence Management

- Identify second sources

- Define last time buy strategies

- Provide effective resolutions to Diminishing Manufacturing Sources and Material Shortages (DMSMS) challenges

- Equipment redesign to design out obsolete items via engineering changes at various system levels, to enhance system performance, and improve reliability and maintainability.

SERVICE LIFE EXTENSION

Refurbish – Recondition

- Inspect, clean, and test equipment

- Identify and replace defective parts before failure occurs

- Return to Condition Code A

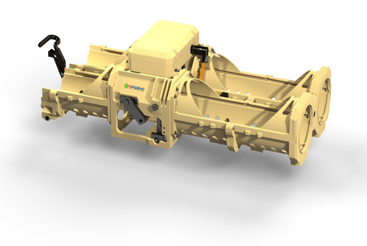

Rebuild

- Renew existing equipment once it reaches its expected end of life service at a fraction of the cost of new replacement

TOW Missile Launcher

Retrofit

- Provide outdated equipment with new technology delivers measurable improvements in performance, reliability, maintainability, overall lifecycle cost and safety of personnel.

- Ensure the overall service effectiveness of legacy systems.

Upgraded TOW Missile Launcher

OPDT Solves the Toughest TOW Challenges

- Legacy TOW Missile Launcher (TML)

- Upgraded TOW Missile Launcher (UTML)

- AN-TAS / ITAS (Ground Launched TOW)

- Upgraded Tripod Mount (UTM)

- TOW Target Acquisition Systems (ISU, BELRF)

- Air-Launched TOW

- Arming Control Unit (ACU)

Team Core Capabilities

Engineering Management

Electro-Mechanical Analysis & Engineering

- Systems Integration

- Rapid Concept Modeling

- Product Simulation

Prototyping & Manufacturing

- Testing & Integration

- Lifecycle Management & Support

International Depot Services and FSR Support

- The effective CLS for CCWS for TOW FMS customers